Product Introduction

High-efficiency road repair machine: Optimized for peak performance, this compact and low-noise repair system simplifies underground tunnel maintenance through advanced mechanization, providing unparalleled operational efficiency.

Core functions

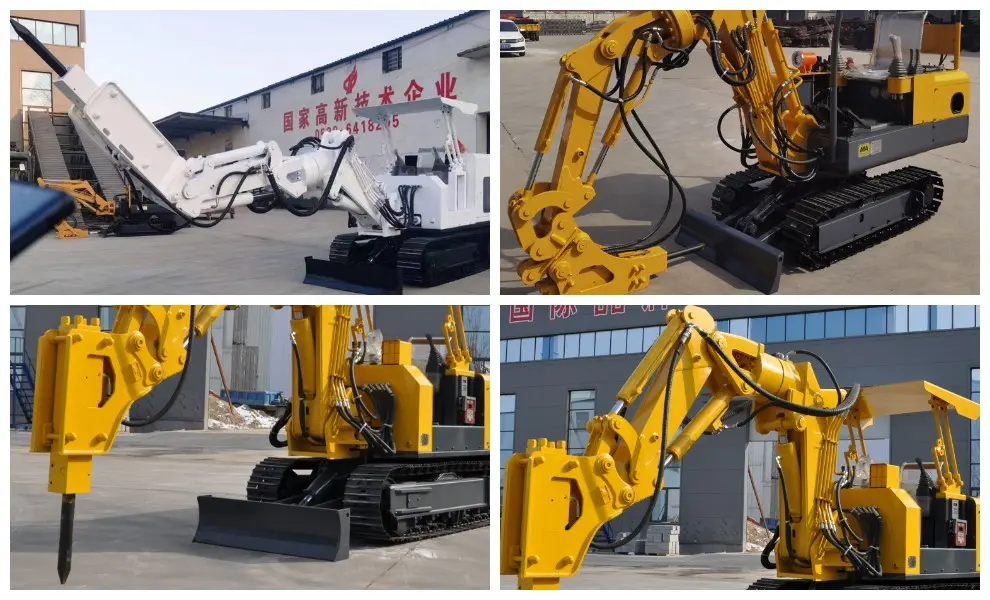

Multi-task articulated arm

Carry out ground lateral excavation and precise material replacement

Integrate six core functions: excavation, rotation, rock crushing, load handling, elevation adjustment and structural cutting (anchor bolt modification)

A complete maintenance toolkit

A special beam manipulator for the installation/removal of structural supports

Manage the formation of drainage channels, surface treatment, coal ash removal and the hygiene of the conveyor belt area

Perform auxiliary operations: compact component processing and local material redistribution

Intelligent hydraulic building

The unified energy-saving power device drives the synchronous hydraulic circuit

Adaptive pressure-sensitive fluid dynamics with precise motion control

Maintain and optimize the layout to enable quick access to service components

People-oriented design

A fatigue-reducing cockpit equipped with a haptic control interface and body support seats

The intuitive operation logic requires very little training

Fault-safe fluid network with directional flow optimization

Adaptive workplace configuration

Instant tool exchange compatibility, suitable for multiple surface treatment modes

Auxiliary hydraulic integration points for special accessories

Dual rear stabilizers, suitable for challenging terrains

Advanced materials processing

An efficient demolition tool with an optimized mass impact ratio

The energy recovery hydraulic circuit minimizes power loss to the greatest extent

Simplified maintenance protocol

Intelligent protection matrix

Atmospheric monitoring

Automatic shut-off protocol for hazardous gas detection and multi-level visual/auditory alarms in critical situations

Fluid guarantee measures

Thermal overload prevention and reservoir integrity monitoring

Anti-collision

Spatial perception technology for workers' close-range management

Remote command

Safe wireless operation, equipped with system health diagnosis function. This engineering solution has completely transformed the underground maintenance workflow, eliminating labor-intensive processes through intelligent mechanization technology. Its modular configuration and adaptive tools provide a comprehensive solution for excavation, material processing and structural reinforcement, setting a new standard for the efficiency of confined space restoration.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||