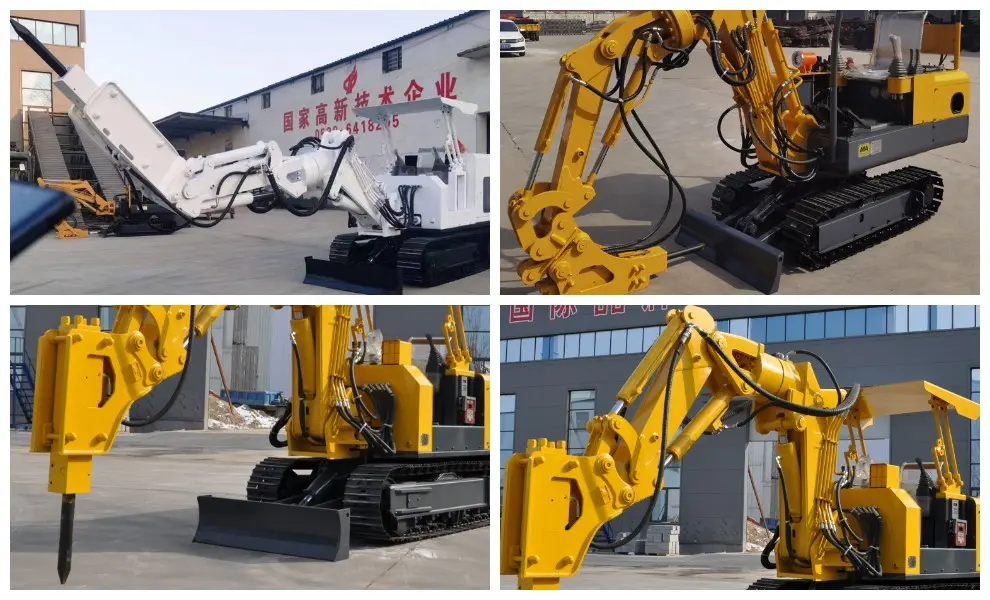

Product Introduction

This excavation system features a robust rotating cutter head and is equipped with hardened cutting tools, which can effectively break down geological structures and thus enable precise excavation of tunnels and passages under various geological conditions. Compared with traditional blasting methods, this technology has significant advantages, including excellent directional control, a smaller ecological footprint and higher operational safety.

Core operational advantages

Precise orientation: Excavation parameters (such as cutting depth and trajectory) are carefully controlled to minimize material waste while maintaining structural integrity.

Performance adaptability: It can operate in various stratum compositions, from consolidated rock layers to heterogeneous soil-rock matrices.

Sustainable operation: The electric drive system minimizes noise emissions and air particulate matter, creating a healthier working environment and meeting environmental protection requirements.

Intuitive control architecture: Integrated automation interface enables rapid adjustment and simplifies operation during the cutting process.

Reduce risks: Eliminate explosive substances, lower potential hazards, and enhance workplace safety standards.

As the cornerstone of contemporary underground engineering, this mechanized cutting solution offers reliable and controllable material removal for mining and infrastructure projects, balancing productivity with ecological and personnel protection requirements.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||