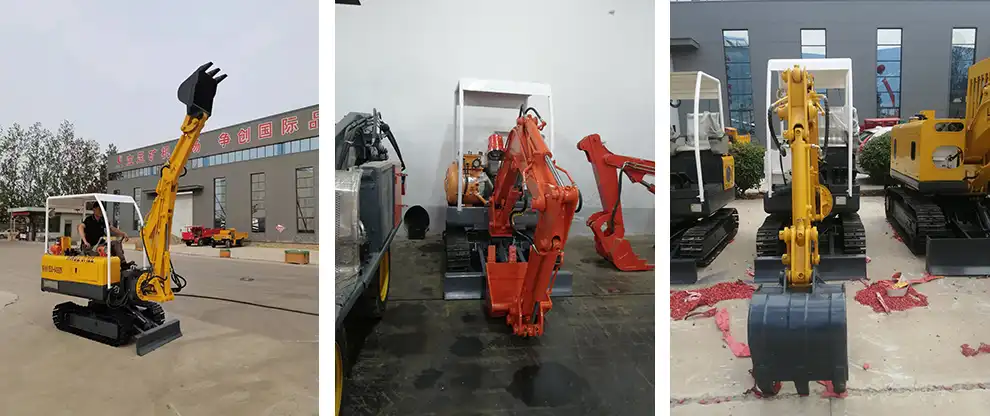

Product Introduction

Electric mining excavators represent a breakthrough solution designed to transform mining operations. Unlike traditional manual bottom cleaning methods, this most advanced machinery significantly reduces labor costs, increases productivity, and provides a safer and more efficient working environment. The operator is shielded in the protective cab to ensure safer operation and better working conditions.

Compared with traditional diesel-powered small excavators, electric mining excavators perform outstandingly due to their electro-hydraulic systems, featuring outstanding advantages such as energy efficiency, noise reduction, zero exhaust emissions, and excellent operational performance. These characteristics make it an ideal choice for underground mining operations, where environmental impact and space constraints are key considerations.

The electric mining excavator adopts a compact and streamlined structural design, occupying less space and having fewer components. This design makes it highly adaptable and easy to operate in vertical or confined areas where traditional equipment may face challenges. In addition, the excavator's innovative minimum swing radius ensures that its tail remains within the vehicle's width when rotating, making it highly suitable for driving in narrow or restricted Spaces. This design feature significantly enhances its effectiveness under challenging mining conditions. In conclusion, electric mining excavators integrate efficiency, safety and environmental sustainability, making them the preferred choice for modern mining operations.

This device is a compact power unit for underground operations, integrating excavation and debris management functions. The automated system significantly reduces the demand for physical labor while enhancing the accuracy of tasks. Ecologically conscious engineering eliminates the common harmful emissions in underground machinery. The innovative spatial design ensures full operation within the narrow mine passage.

Product application

Electric mining excavators are highly adaptable machines designed to handle various tasks in mining environments. It performs outstandingly in rock loading, bottom cleaning and permafrost excavation in various mining sectors such as coal, metal and non-metal mines. Its compact and efficient design makes it particularly suitable for use in confined Spaces that require dedicated equipment, such as shafts, inclined shafts and flat tunnels. With its energy-saving performance, zero emissions and compact structure, the electric mining excavator is an ideal choice for challenging underground conditions, which can increase productivity while promoting safer and more environmentally friendly mining practices.

Project |

"Unit | MWD8/0.35 L | ||

The structural form of the working body |

/ |

Three-section arm |

||

The rotation Angle of the auxiliary arm |

° |

+ 90 ° |

||

Motor power |

Kilowatt |

75 |

||

Hydraulic system |

Rated pressure | MPA | 23.5 | |

| Main pump flow rate | Liters per minute | 140 | ||

| Types of hydraulic pumps | / | Variable displacement pump | ||

| A walking driving style | / | Integrated hydraulic motor reducer drive | ||

Walking mechanism |

Walking form | / | Tracked driving | |

| Compare the ground pressure | MPA | ≤0.1 | ||

| Driving speed | Kilometers per hour | 0-3.5 | ||

| Ground clearance | millimeter | 300 | ||

| Climbing ability | ° | 15 | ||

| Swing Angle | ° | 360 | ||

| Swing speed | Revolutions per minute | 0-10 | ||

| Tracked type | / | Steel track | ||

| Full track length | millimeter | 2450 | ||

| Track width | millimeter | 400 | ||

Bucket loading |

Bucket capacity | Cubic meters | 0.35 | |

| Excavation radius | millimeter | 5150 | ||

| Maximum elevation Angle arm height | millimeter | 5400 | ||

| Maximum emission height | millimeter | 4000 | ||

| Maximum mining depth | millimeter | 2550 | ||

| Tail swing radius | millimeter | 1670 | ||

| Bucket digging force | KN | 40 | ||

| Nominal work pressure | MPA | 11-14 | ||

Hydraulic breaker |

"Process" | Liters per minute | 40-70 | |

| Impact frequency | Rotational speed | 500-900 | ||

| Impact energy | J | 540 | ||

| Appropriate specifications of brazing tools | millimeter | 68 | ||

| Noise | Decibel (A | ≤120 | ||

| The width of the bulldozer blade *H | millimeter | 1900 x 370 | ||

| Overall external dimensions (length * width * height) | millimeter | 3800 * 1900 * 2500 | ||

| Weight | t | 8.2 | ||