Product Introduction

Electric operating efficiency

These systems adopt motor drive technology, prioritize flexible functions, and reduce maintenance requirements. Its energy-saving design enables zero-emission operation and higher reliability. Compared with internal combustion engines, it can significantly reduce electricity costs.

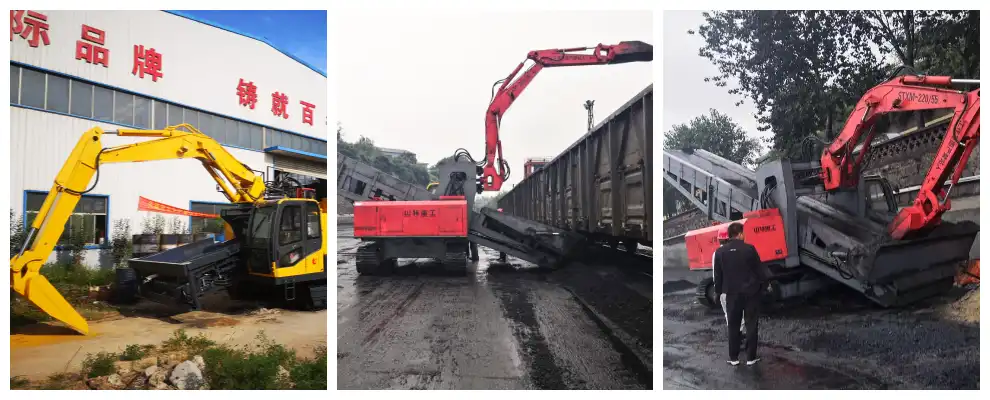

Simplified material handling process

Bulk materials are seamlessly conveyed from the unloading device to the transportation unit by a post-mounted conveyor, eliminating the intermediate contact between the materials and the surface and suppressing the diffusion of particulate matter in the air. This approach promotes sustainable resource management while reducing the impact on the ecological environment.

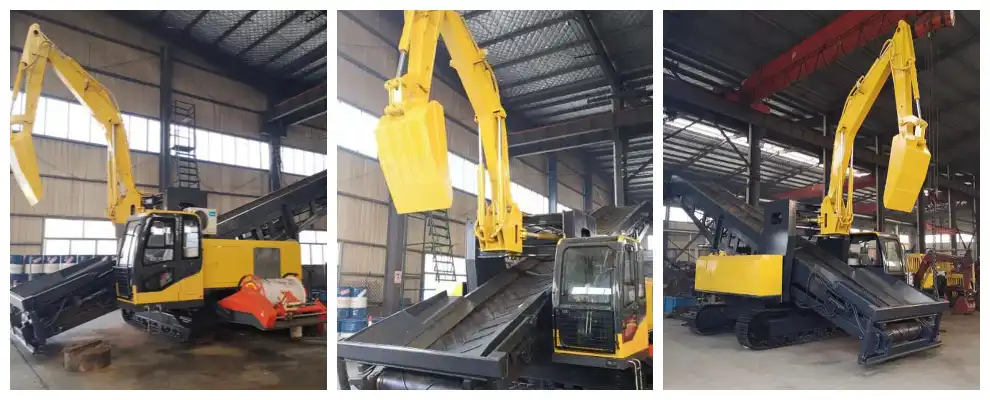

Compact loading interface design

The space-saving closed feeding structure can prevent material leakage onto the track infrastructure, thus keeping the track running smoothly. This configuration ensures a cleaner workspace and reduces the need for residue removal after work.

Comprehensive rail vehicle clearance capability

The extended mechanical extension range is conducive to thoroughly extracting materials from transport containers, minimizing residues and reducing labor reliance on manual cleaning tasks.

Intelligent Environmental Management

This device adopts an adaptive ventilation mechanism to ensure continuous air renewal, and at the same time uses an environmentally friendly thermal regulation method. Programmable climate management enhances energy-saving temperature regulation.

Enhanced operation synchronization

Coordinated hydraulic integration and process automation can accelerate the material transfer cycle and offer superior throughput efficiency compared to standard mechanical alternatives.

Train coal unloader |

|||

| Project | Unit | STX-220 | |

| Overall dimensions - length × width × height | millimeter | 10277 * 5530 * 3550 | |

| Working weight | T | Material 20 | |

| Efficiency | Tons of lump coal per minute | 3-10 | |

| Bucket size | millimeter | 1250 * 950 * 450 | |

| Engine | Main motor power | Kilowatt | 55 |

| Rotational speed | Revolutions/minutes | 1450 | |

| Belt motor power | Kilowatt | 22 * 2 | |

Hydraulic system |

Main pump | / | Imported variable piston pump |

| Rated flow | Liters per minute | 220 | |

| Work pressure | Megapascal | thirty | |

| Main valve | / | Rexroth | |

| Capacity of the hydraulic oil tank | The left | 220 | |

| Walking motor | / | Doosan, South Korea | |

Performance parameters |

Belt speed | Multiple sclerosis | 2 |

| Belt width | meter | 1.2 | |

| Belt Angle | ° | 22 | |

| Fully enclosed cab | / | Aviation seats and hydraulic operation | |

| Automatic cable arrangement device | meter | 100 | |

| Electrical system | Santak Heavy Industry | ||

| Oil cylinder | Imported seals (Constant force) | ||

| Hose | Italian/Qingdao Oak VI | ||