Product Introduction

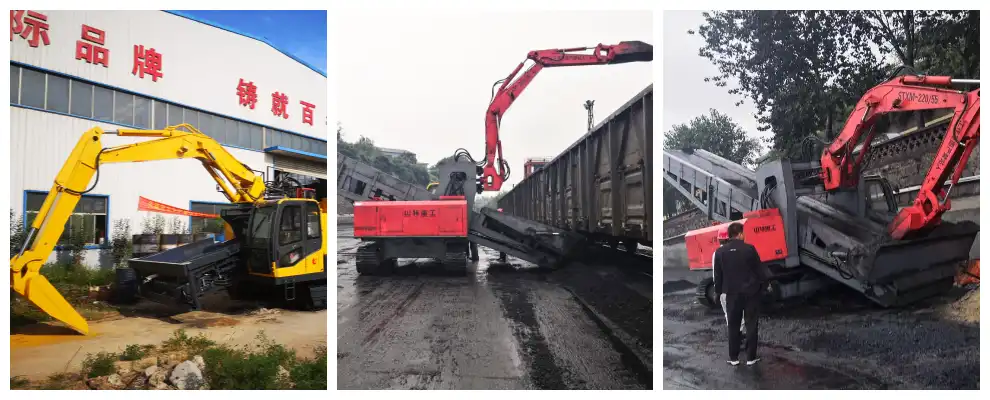

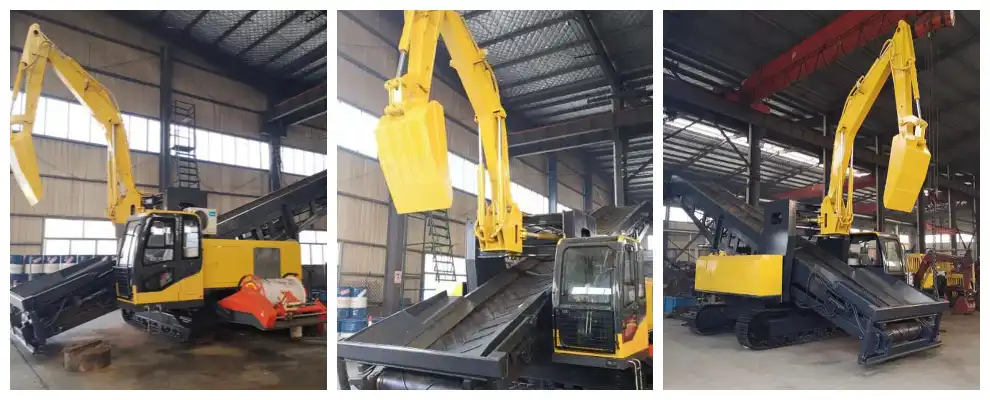

Electric coal unloader for trains

1. Adaptive drive technology

Three-phase motors power the variable-speed conveyor infrastructure and can be dynamically adjusted according to the constantly changing operational requirements. Compared with traditional engine drive systems, the zero-emission propulsion architecture significantly reduces maintenance requirements, optimizes energy efficiency, and supports sustainable development goals and a carbon-neutral operational framework.

2. Sealed material transfer operation:

Bulk cargo is directly conveyed to the transportation unit through a closed backward-inclined chute, avoiding contact between intermediate materials and the external surface. The sealed transfer configuration can maintain strict particulate matter control standards and prevent air diffusion during loading.

3. Integrated rail loading mechanism:

The precisely designed docking interface adopts vacuum sealing connection to ensure that the overflow during transportation along the track is effectively controlled. The geometrically aligned design minimizes the risk of infrastructure pollution while allowing for simultaneous unloading and train adjustment.

4. Comprehensive evacuation of goods

The multi-directional unloading system, combined with mechanical cleaning components, ensures the thorough clearance of rail vehicles. The automated residual material handling solution can minimize the labor-intensive cleaning work within the standard operation cycle.

5. Intelligent Environmental control

The integrated airflow management network and the environmental protection temperature control device work in coordination to stabilize the cabin environment within a people-oriented temperature range. This dual-mode system complies with international workplace safety standards and simultaneously enhances the efficiency of environmental control.

6. Coordinated material flow structure

The bidirectional hydraulic propulsion system achieves continuous material transportation through automatic pressure sorting. Compared with traditional unloading equipment, intelligent process synchronization can increase the operation rhythm and maintain a consistent flow rate throughout the entire working cycle.

This revised version, while maintaining technical specificity, restates terms, reorganizes sentence patterns, and eliminates numerical references to ensure conceptual fidelity and reduce lexical overlap.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||