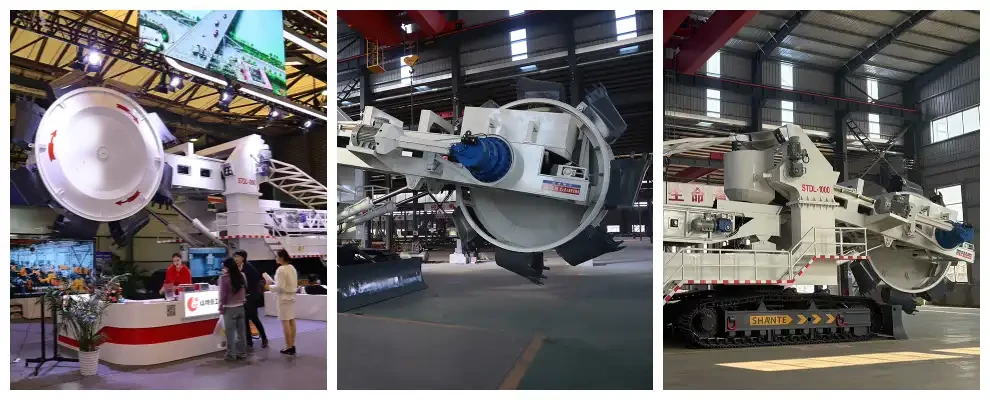

Product Introduction

Remote-controlled bucket wheel stacker-reclaimer

Outstanding productivity: The bucket wheel stacker-reclaimer boasts an unparalleled loading capacity, capable of efficiently handling large-scale materials within a single operation cycle and achieving continuous transportation. Its ultra-fast loading/unloading cycle ensures the rapid completion of complex tasks, thereby significantly enhancing industrial productivity.

Versatile functions: This machine is flexibly designed and highly adaptable, suitable for various industrial environments, ranging from coal terminals, port logistics centers to construction projects, steel production facilities, chemical plants, and precision material stacking applications. It can do anything. Its universal design can handle various operational challenges and ensure seamless integration across industries.

Zero downtime operation: The bucket wheel stacker-reclaimer is designed for industrial-grade durability, providing uninterrupted performance and 100% uptime, outperforming traditional loading/unloading systems in terms of speed, flexibility and operational consistency.

Outstanding performance and precision: This machine adopts a high-torque propulsion system and precisely calibrated conveyor belt technology, enabling rapid material transfer and millimeter-level precise stacking. Ai-driven predictive analysis and real-time diagnostic capabilities can enhance operational safety, preventive maintenance and fault resolution capabilities, ensuring uninterrupted workflow.

Easy maintenance: The modular framework supports rapid component replacement and simplified maintenance protocols, significantly reducing downtime and total cost of ownership. The pre-configured module supports immediate access to key components, maximizing uptime and enhancing lifecycle efficiency.

Intuitive and easy to use: With ergonomic control devices and a user-oriented interface, operators can master the operation with minimal training. Proficient in core functions and strictly adhering to safety regulations to ensure consistently high productivity without any advanced technical expertise.

Remote-controlled bucket wheel stacker-reclaimer |

|||

Project |

Unit | Technical specifications | |

| Overall dimensions - length × width × height | millimeter | 21090 * 4000 * 5888 | |

| Track size | millimeter | 5700 x 600 | |

| Track plate width | millimeter | 600 | |

| Track-driven hydraulic motor | / | Hydraulic motor + reducer | |

| Teack drives the hydraulic pump | / | Danfoss | |

| Hydraulic pump drive motor | Kilowatt | 45 | |

| The bucket wheel arm is long | millimeter | 8280 | |

| Length of the unloading arm | millimeter | 8000 + 3000 | |

| Rated output | Cubic meters per hour | 900 | |

| Bucket wheel diameter | millimeter | 3600 | |

| Bucket wheel rotational speed | Revolutions/minutes | 0-8 | |

| The volume of each bucket wheel | Cubic meters | 0.3 | |

| The number of buckets | slice | 8 | |

| Bucket wheel pitch Angle | ° | 25 ~ 5 | |

| Material density | Tons per cubic meter | 0.8 ~ 1.8 | |

| Turning radius of the bucket wheel | millimeter | 10036 | |

| Width of the material taking conveyor belt | millimeter | 1200 | |

| The rotation Angle of the bucket wheel | ° | + 180 | |

| Width of the unloading conveyor belt | millimeter | 1000 | |

| Length of the unloading conveyor belt | millimeter | 29524 | |

| The rotation Angle of the unloading conveyor belt | ° | + 65 | |

| Pitch Angle of the unloading conveyor belt | ° | 0-16 | |

| The maximum stacking height of the unloading conveyor belt | millimeter | 6500 | |

| Drive form of telescopic mechanism | / | Hydraulic cylinder | |

| Overload protection method for bucket wheels | / | Automatic | |

Matching motor power |

Track walking drive | Kilowatt | 45 |

| Bucket wheel swing drive | Kilowatt | 75 | |

| Bucket wheel conveyor belt drive | Kilowatt | 15 * 2 | |

| Discharge conveyor belt drive | Kilowatt | 15 * 2 | |

| Engine power | Track walking drive | Kilowatt | 105 |