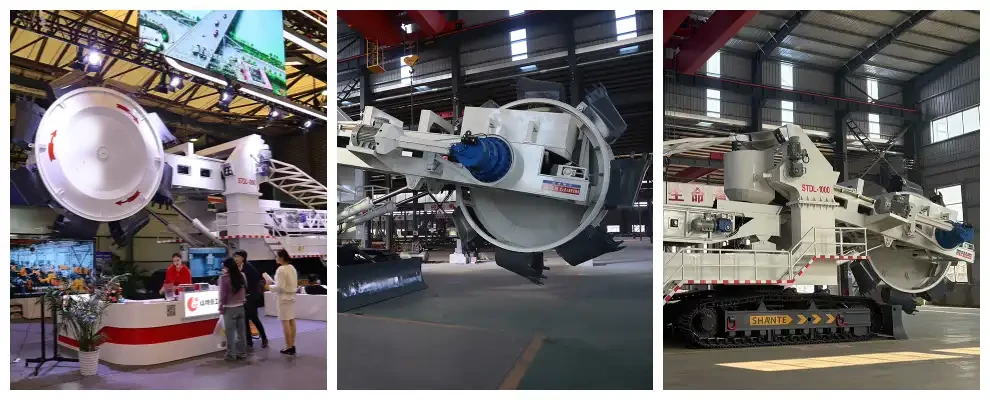

Product Introduction

Enhance operational efficiency: The bucket wheel reclaimer has a powerful material handling capacity, integrating bulk cargo management and transportation into an integrated workflow. Its rapid transfer speed enables it to complete large-scale operations quickly, significantly improving throughput efficiency and minimizing project duration to the greatest extent.

Flexible functionality: This device is specifically designed for flexible deployment across industrial environments and is suitable for coal distribution centers, Marine logistics terminals, infrastructure projects, metal processing plants, and chemical production plants. Its configurable architecture supports diverse material stacking requirements and operational scales in multiple industries.

Operational capacity: This system is specifically designed for continuous working cycles, maintaining consistent workflow continuity without the need for forced pauses. Compared with traditional bulk handling machinery, it offers outstanding uptime performance while eliminating productivity gaps.

Precision Engineering and operational Integrity: This device employs optimized propulsion technology and an advanced material conveying system to ensure rapid distribution of goods and achieve millimeter-level stacking accuracy. The combination of intelligent automated interfaces and predictive diagnosis ensures operational safety, equipment health monitoring, and immediate anomaly detection.

Maintenance optimization design: The modular architecture helps to achieve efficient maintenance procedures and rapid parts replacement, effectively reducing equipment idleness time, while maintaining cost-effective life cycle management through simplified maintenance protocols.

Operator-centered interface: The user-centered control system, designed with intelligent ergonomics, enables quick familiarization with operation. Comprehensive system management only requires basic training in functional parameters, process sequencing, and security compliance protocols, without any professional technical qualifications.

Project |

Unit | STDL-500 | STDL-1000 | STDL-1600 | STDL-2600 |

| Overall dimensions (length × width × height) | millimeter | 17100 * 3600 * 4680 | 21100 * 4000 * 5900 | 25000 * 5000 * 72800 | 30000 * 5900 * 8300 |

| Bucket wheel diameter | millimeter | 3000 | 3600 | 4500 | 5800 |

| The bucket wheel arm is long | millimeter | 6980 | 8280 | 9280 | 11280 |

| Bucket wheel volume | Cubic meters per piece | 0.2 | 0.3 | 0.4 | 0.42 |

| The number of buckets | slice | 8 | 8 | 10 | 14 |

| Rated output | Cubic meters per hour | 500 | 1000 | 1600 | 2600 |

| Material density | Tons per cubic meter | (0.8-1.8) ×10³ | (0.8-1.8) ×10³ | (0.8-1.8) ×10³ | (0.8-1.8) ×10³ |

| Length of the unloading arm | millimeter | 7000 + 3000 | 8900 + 3400 | 9000 + 4000 | 9000 + 5000 |

| Length of the unloading conveyor | millimeter | 25000 | 33375 | 33375 | 36000 |

| The maximum stacking height of the unloading conveyor | millimeter | 5500 | 6500 | 7000 | 8000 |

| Power | Kilowatt | 200 | 295 | 420 | 509 |